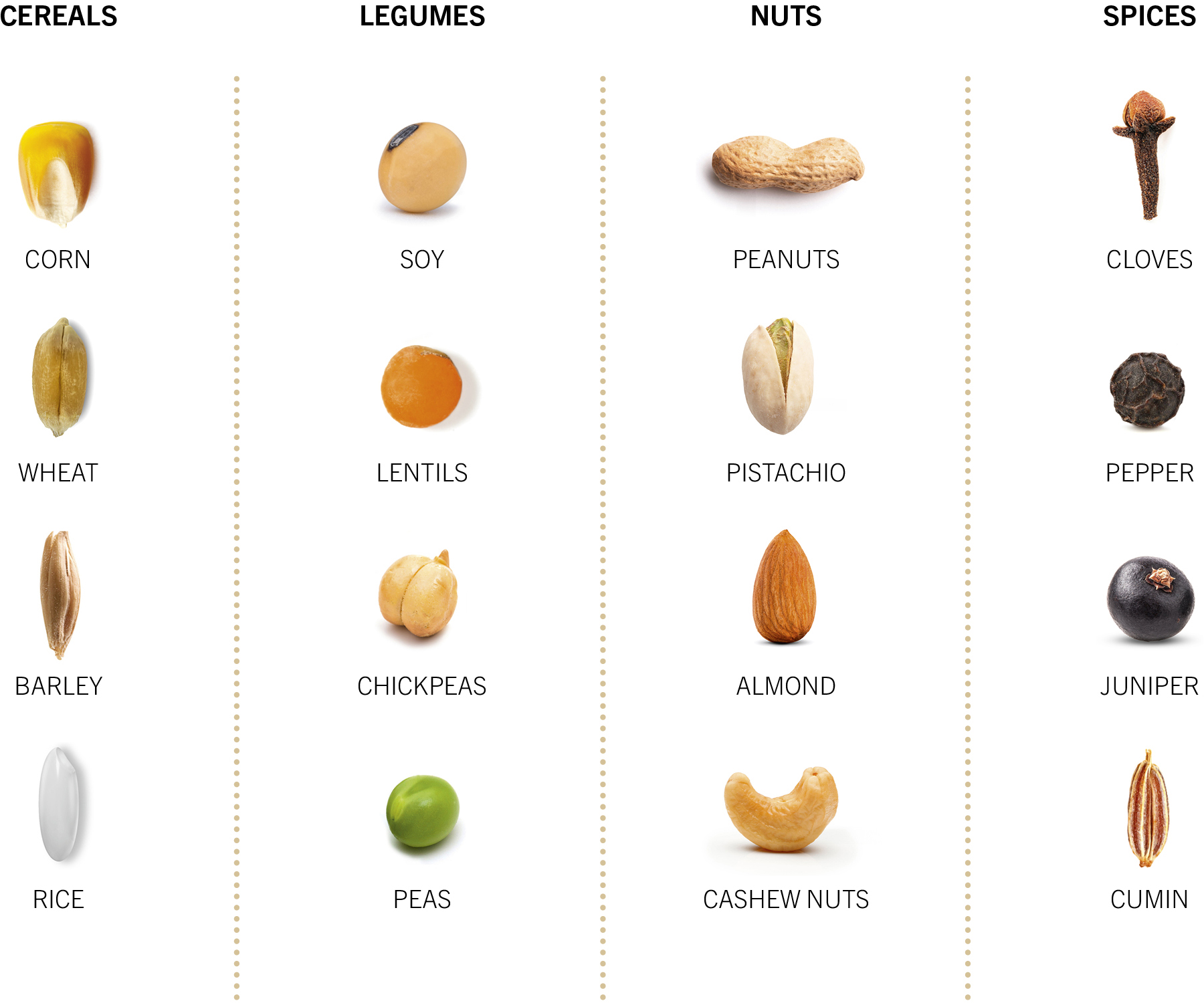

Cereals, legumes, dried fruit, and spices are the main categories of processed products.

Design and Manufacturing of Plants and Systems for the Food Industry

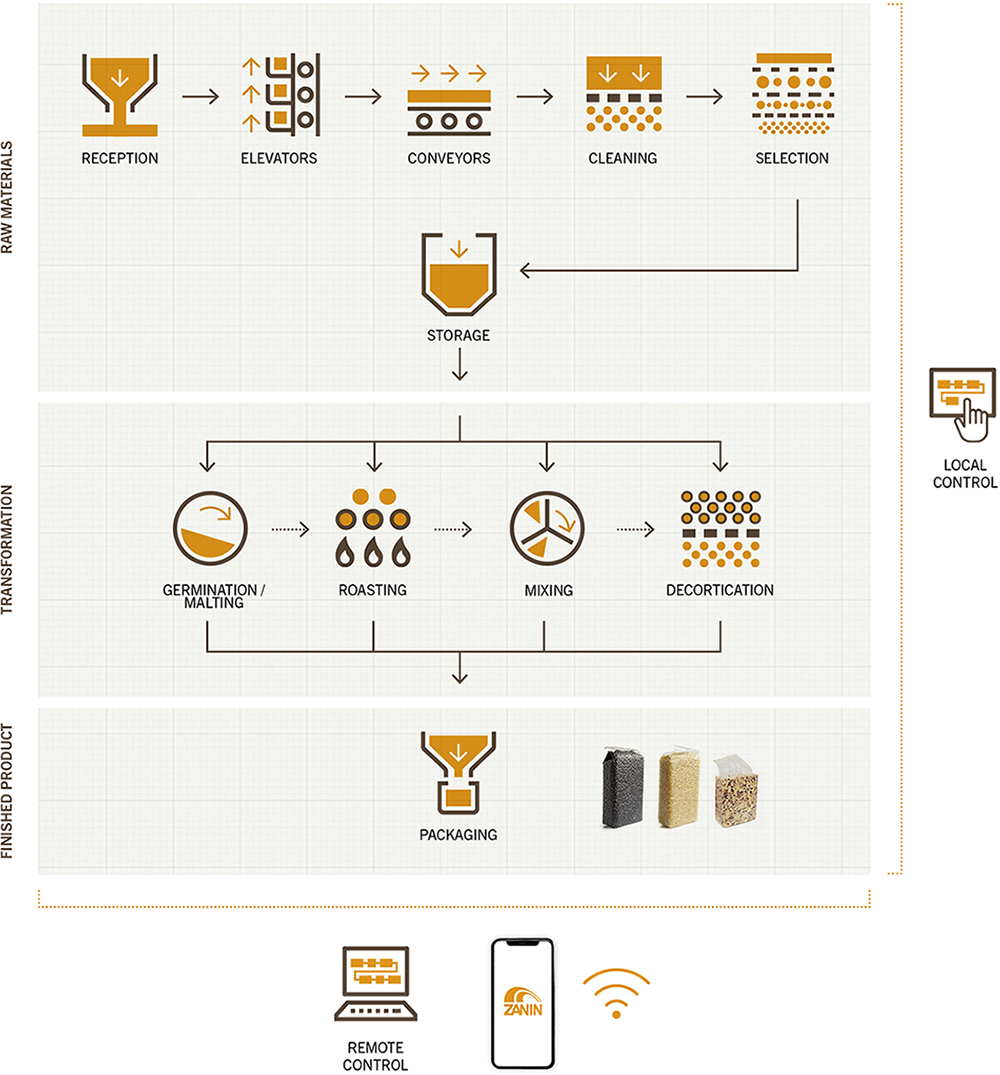

Cleaning, handling equipment, and storage systems; malting, roasting, dehulling, and mixing systems.

We started our business back in 1956. Since then, we have grown to become a world-leader in the design, manufacture and construction of plants for cleaning, drying, handling and storing cereals. For the food sector, we design and manufacture machines and plants for the production of malts, and for the processing of cereals, legumes, spices, and dried fruit.

The design and construction of our plants are tailored for every type of seed, with specific solutions for the production cycle: seed cleaning, selection and dehulling, horizontal and vertical transportation, storage and ventilation, dosing and mixing of seeds and flours, malting, roasting, and packaging. Our range of highly specialized and innovative systems and machines is the answer to a constantly evolving market.

Zanin: History and Evolution

Zanin was founded in 1956 by Giuseppe and Arcangelo Zanin. Initially, it focused on the production of dryers for silkworms and later on the creation of plants for drying cereals. On these solid foundations, it secured a prominent position in the agri-food market.

The company, managed by Oscar Zanin, is engaged in constant development and consolidation. Always up-to-date with the latest processing systems and new technologies, Zanin s.r.l. manufactures its products based on the most advanced criteria of:

- High specialization

- Custom design

- Quality of processes and products

- Efficiency and flexibility

- Corporate culture of “problem solving” in customer service

Zanin: Systems and Machines for the Agri-Food Industry

Since 1956, Zanin has been designing and manufacturing machines and plants such as cleaners, dryers, conveyors, and storage systems for the agri-food industry and for the industry in general. It is highly specialized in the production of machines and plants for processing cereals, seeds, and legumes, as well as in dehulling, pelleting, and fertilizer treatment.

Zanin's experience and plants are also often applied in railway and port logistics, in the processing of coal, plastics, glass, and for the industry in general.

Zanin is organized into several highly specialized production lines: AGROINDUSTRY, FOOD, INDUSTRY, and LOGISTICS.

With our flexibility and extensive know-how, we always design and create the best custom solutions tailored to meet each of our clients' needs.

100,000

components designed

every year

1,000

installations

in 2022

250+

satisfied

customers

Food Evolution, Our Company Leads the Way

On our tables, we want food products that are increasingly natural and of high quality. At Zanin, we are aware of this virtuous evolution of the market. We play a leading role in the agri-food sector of FOOD, leveraging our experience gained over more than 60 years, our professionalism, and our vision. Modern technological plants for malt production. Certified cleaners for processing cereals and legumes. Automated mixers for flours. These are some of the certified systems we design and manufacture to contribute to the realization of a better and more sustainable future.

Design

A team of engineers studies the project according to the client's requirements. After careful study, the actual design phase begins using the most modern 3D drawing tools.

Construction

The order is sent to the production department and enters the manufacturing phase. Computer-controlled machines and skilled workers ensure the perfection of the produced components. A computerized management system allows real-time progress tracking.

Assembly

All systems are pre-assembled in-house for internal quality control. Once the machines' conformity is verified, they are disassembled and prepared for shipping.

Support

A punctual and effective after-sales service is always available to the customer. Zanin is always ready to support the customer at every stage of the plant's life cycle with seriousness and professionalism.