SINGLE STEP HULLING SYSTEM

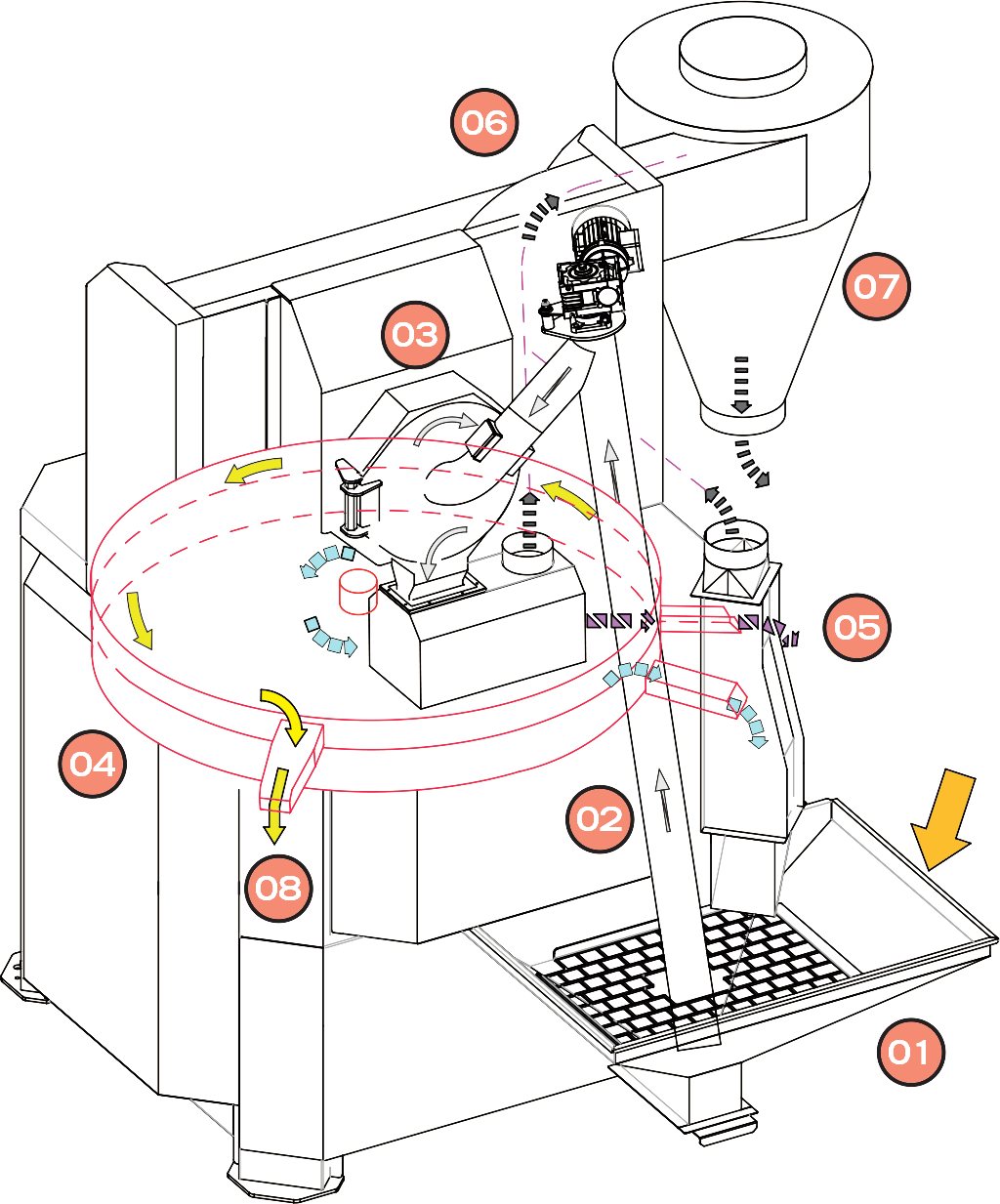

OPERATION

The product enters by gravity into a screw in the dehulling system, where it slipped through centrifugal action. Subsequently, the product passes through a perforated basket, which changes depending on the type of product to be treated, then exits from the decortication unit.

The vacuum system separates the light output (glumes) from the (corn) grain, which is sent to an oscillating separation system. This system is designed to separate the good product, which comes out in the outer part of the plate, and the waste, which is rejected falling in the central part and returing then to the auger.

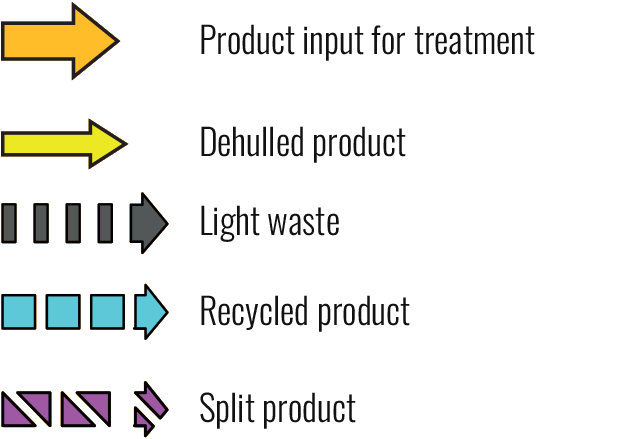

LEGEND

01 - Product entry hopper

02 - Feeding Auger

03 - Dehuller

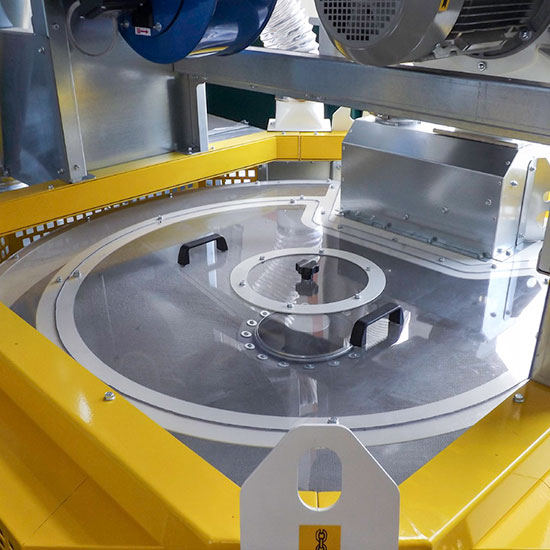

04 - Swashplate

05 - Split product outlet

06 - Aspirator

07 - Cyclone

08 - Dehulled product outlet

CONTROL PANEL

SWASHPLATE

OUTLET OF THE HUSKED PRODUCT

DEHULLER UNIT WITH OUTLET DRAWER

COMPONENTS

- Tubular frame supportwith reinforcement sections.

- Tubular fairing with protective plate.

- Ballast with concrete slabs.

- Tubular feeding screw conveyor.

- Iron-removal in the product output auger.

- Dehuller rotor./p>

- Product outlet drawer with suction.

- Swashplate in carbon steel with sieve.

- Control panel complete with inverter.

- Decanting cyclone.

HULLER TECHNICAL SPECIFICATIONS

| MODEL | DEC 5 | DEC 7 | DEC 11 |

|---|---|---|---|

| Capacity inlet product (t/h) | 0,4 | 0,6 | 0,9 |

| Sieves surface (m2) | 1,39 | 1,39 | 1,39 |

| Auger electric power (kW) | 0,55 | 0,55 | 0,55 |

| Deuller electric power (kW) | 5,5 | 7,5 | 11 |

| Sieve electric power (kW) | 1,1 | 1,1 | 1,1 |

| Fan electric power (kW) | 0,75 | 0,75 | 0,75 |

| Length (mm) | 2199 | 2199 | 2199 |

| Width (mm) | 2388 | 2388 | 2388 |

| Height (mm) | 2384 | 2384 | 2384 |

| Empty Weight (kg) | 802 | 817 | 824 |

NB: Capacity in spelt. Relative Humidity 14%, cleaned product. Specific weight 0,60 t/m3. Capacity is referred to entered product. OPTIONAL: antiwear plate, trailer, bag placer, star valve.

PROCESS MANAGEMENT AND CONTROL

To improve production processes in the agri-food industry, automated systems are used to control the entire production organization

through interconnection between machines. These systems allow for gathering all the necessary information for product traceability; they also enable

planning and verifying maintenance intervals for machines.

Process management can be done remotely, allowing monitoring of machine operation, collecting information to be sent to Big Data, managing scheduled,

extraordinary, and emergency maintenance interventions for the plant. All of this is accessible securely from anywhere via web, app, or mobile.