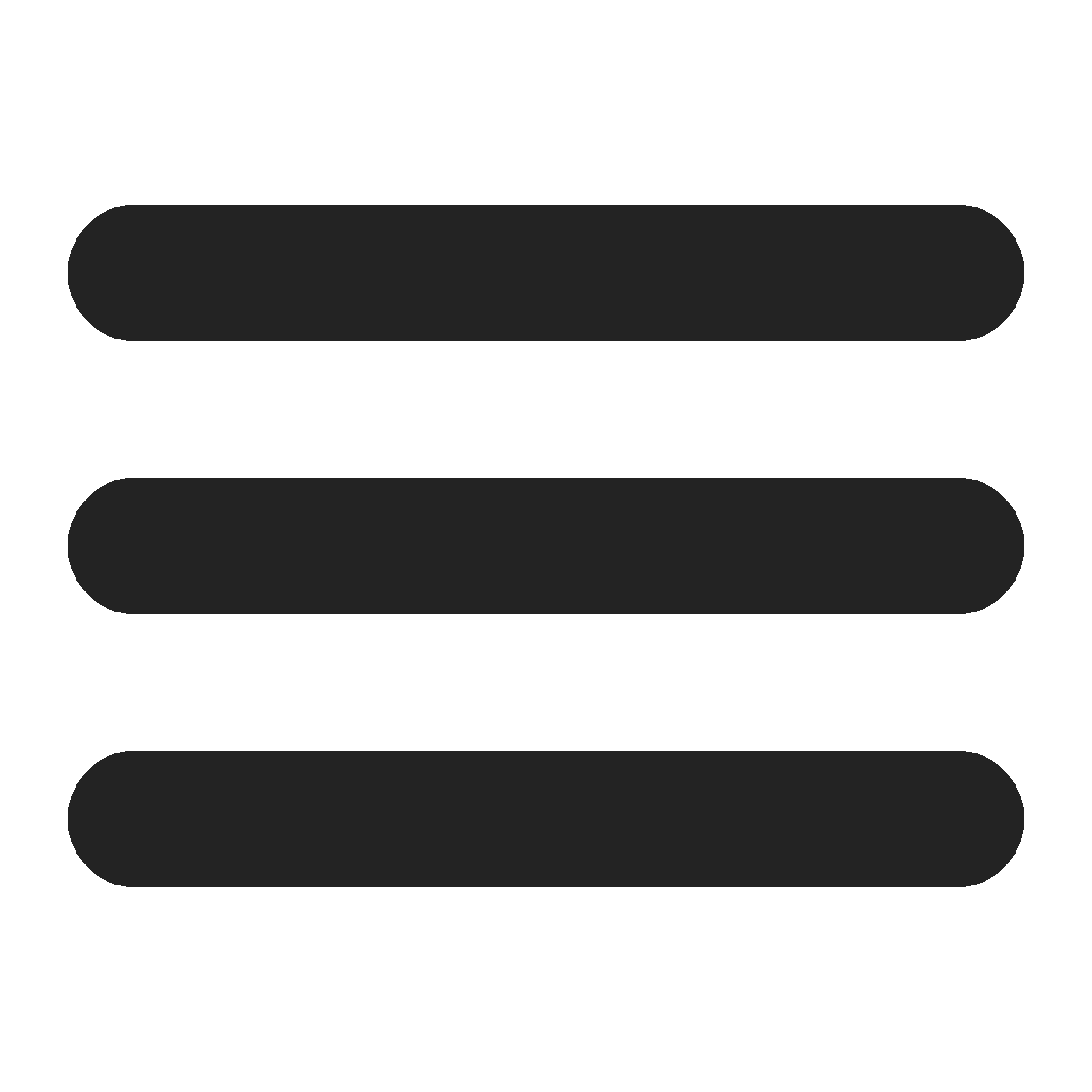

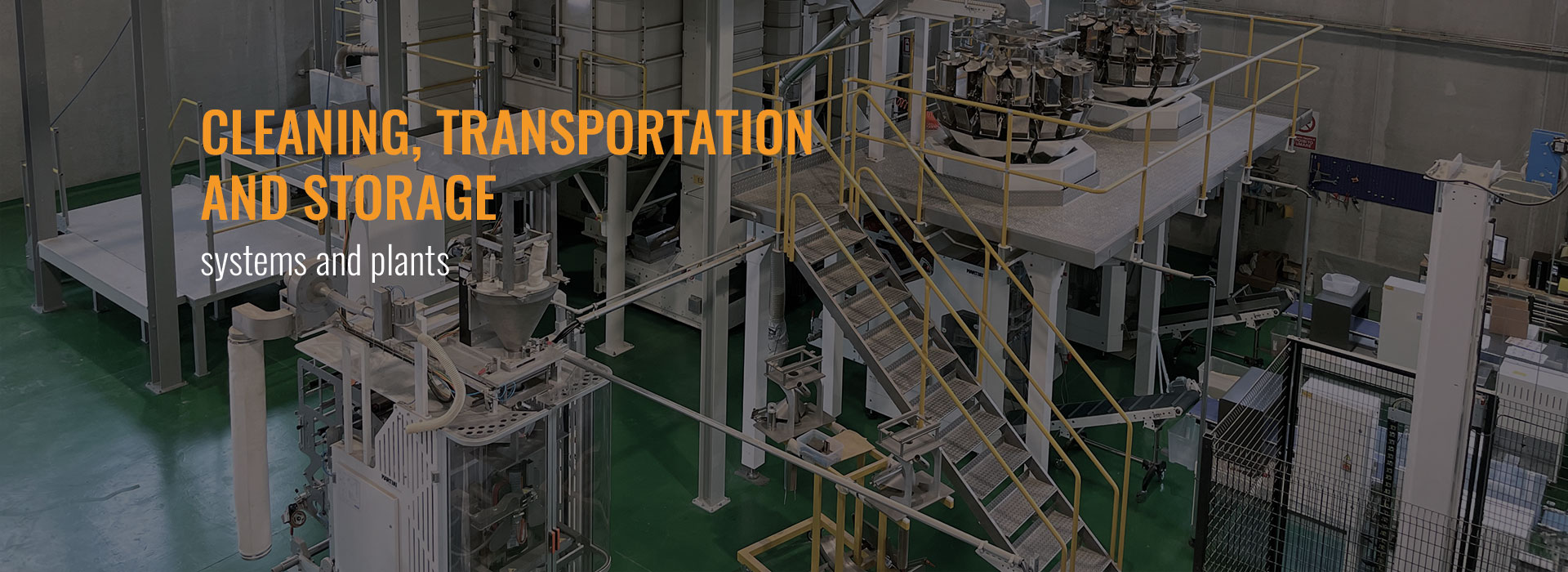

Cleaning, transportation and storage systems and plants.

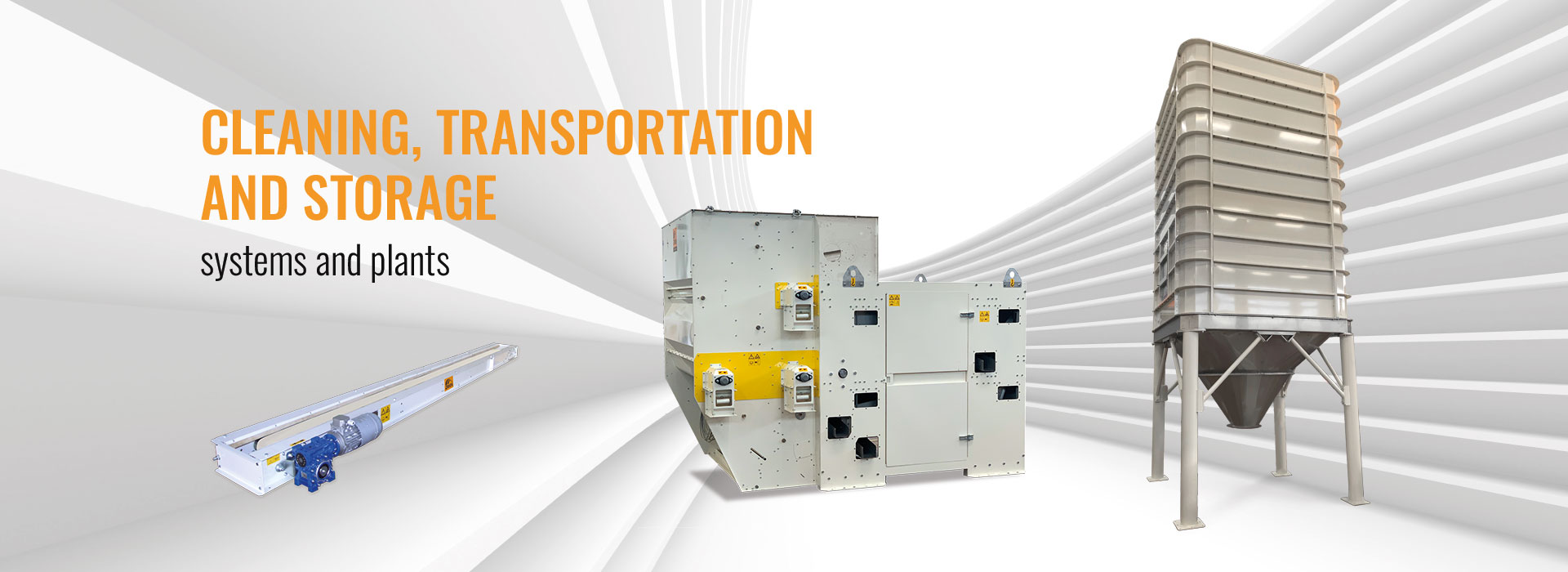

Every plant requires systems for transportation, cleaning, and storage. Zanin creates customized plants based on the individual needs of the customer. From receiving to packaging, Zanin can provide machines for "gentle" transportation, for removing impurities and foreign bodies, and for storing the product before a processing or packaging phase.

STORAGE SILOS

Storage silos are usually custom-made according to the final customer's requirements. However, what unites all Zanin silos is:

- Smooth internal walls to prevent deposits

- Anti-breakage spiral descenders

- Presence of large hatches for internal cleaning

- Use of high-quality materials

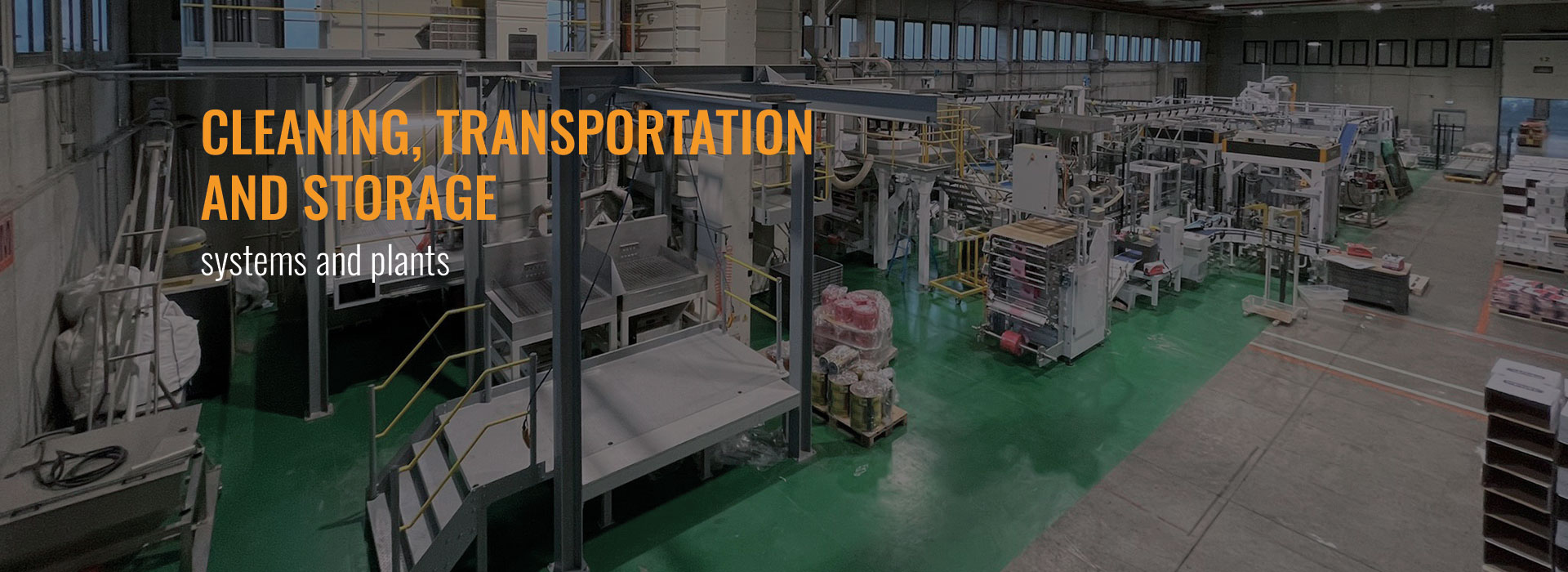

SIEVE CLEANERS

Zanin sieve cleaners are essential for the quality of the finished product. They are able to remove impurities of different natures through the use of perforated screens and aspiration adjustments. If mechanical cleaning is insufficient, Zanin also offers additional machines such as gravimetric tables and optical sorters.

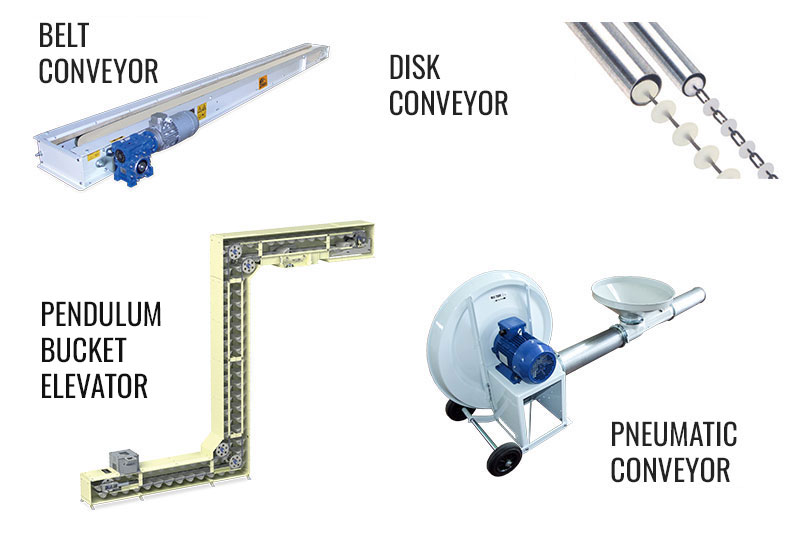

CONVEYORS

Different products have different needs. Zanin, aware of this, is able to recommend the type of transportation that best suits the needs of the process itself. The wide range of available conveyors allows for comprehensive coverage in the food products landscape. Consequently, it ensures customer satisfaction.

Dust Stop Hopper

Our patented hopper that concentrates and blocks dust

Our patented hopper DS - DUST STOP is used for any type of dusty load and makes filtration systems unnecessary. Our DS - DUST STOP hopper system concentrates all the dust already within the product flow (see flow diagram). This ingenious innovation naturally blocks the dust that would otherwise be generated during the product fall phase.

For more information, visit www.duststophopper.com

PROCESS MANAGEMENT AND CONTROL

To improve production processes in the agri-food industry, automated systems are used for the control of the entire production organization

through interconnection between machines. These systems collect all the necessary information for product traceability; they also allow for planning and

verifying machine maintenance intervals.

Process management can be done remotely and allows for monitoring machine operation, collecting information to send to Big Data, managing scheduled,

extraordinary, and emergency maintenance interventions of the plant. All this is accessible securely from anywhere via web, app, or mobile.