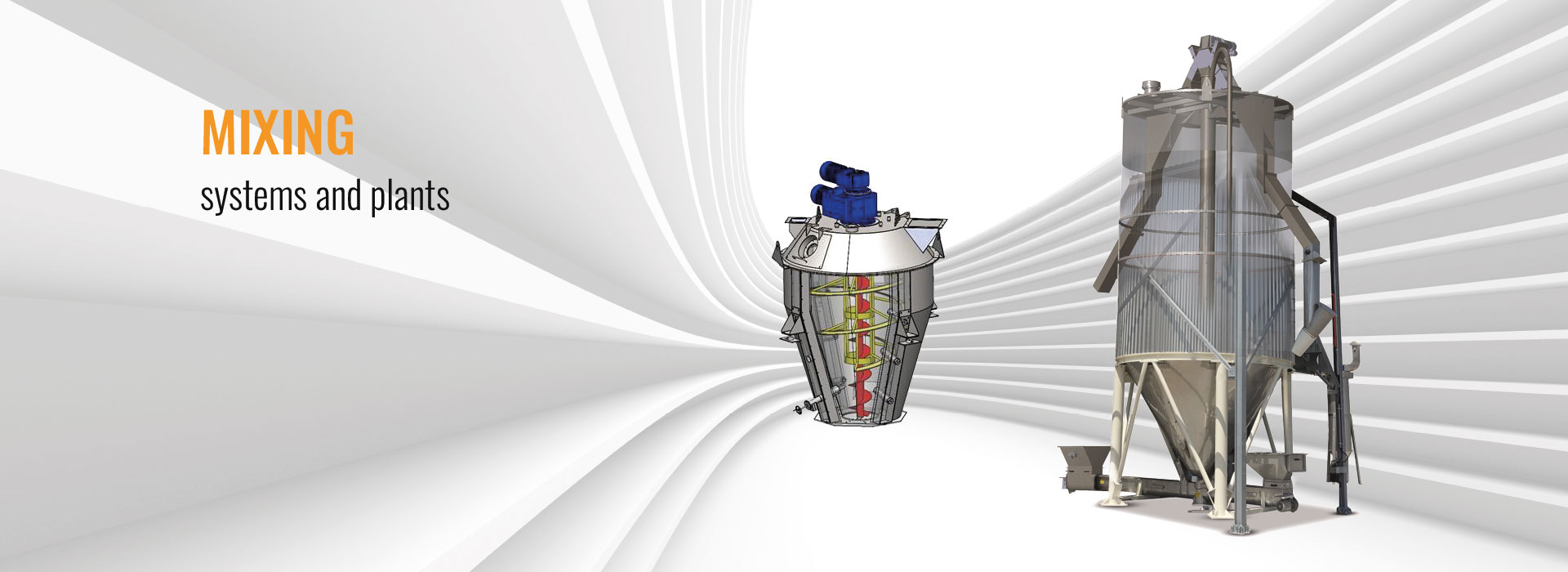

Mixing systems and plants

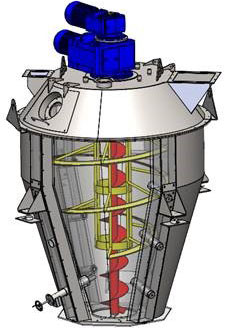

BATCH MIXERS FOR CEREALS AND LEGUMES

Zanin mixers are designed for optimal mixing of cereals and legumes according to a predefined recipe. The mixing system ensures product uniformity while maintaining the structural integrity of the seed. Cleaning operations, essential in the food sector, are extremely simple thanks to the installed washing CIPs and the large access hatches inside the machine. Speed and precision are the essence of Zanin mixers.

HIGH-VOLUME FLOUR MIXERS

These high-capacity flour mixers are designed and manufactured to meet the need for batch uniformity while minimizing processing times. Process management is entrusted to software that allows setting and storing different types of recipes. At the end of processing, the product is ready to be loaded onto tank trucks and sent to the packaging area.

PROCESS MANAGEMENT AND CONTROL

To improve production processes in the agri-food industry, automated systems are used to control the entire production organization

through interconnection between machines. These systems allow for gathering all the necessary information for product traceability; they also enable

planning and verifying maintenance intervals for machines.

Process management can be done remotely, allowing monitoring of machine operation, collecting information to be sent to Big Data, managing scheduled,

extraordinary, and emergency maintenance interventions for the plant. All of this is accessible securely from anywhere via web, app, or mobile.