MALTING SYSTEMS for cereals and sprouted seeds

The manufacturing of malting plants has been a natural step for our company, coming from experience acquired in the

production of machines for cereal processing combined with a greater sensitivity in the food industry.

After decades of products obtained from large transformation cycles, there is now a trend towards regionalization. Therefore the

production of its own malt has regained importance for small and medium-sized companies. Mostly for craft breweries,

terms like "origin" and "territory", now play a key role in their activity.

The production of malt from local cereals creates a lot of interest. "Local" concepts are becoming more and more popular. Primarily in the food industry, health and traceability are the topics of high interest for final consumers. This determines a step forward in the production of organic products. The slogan “from field to drinking glass” becomes important as the brewery, in addition to beer, produces its own malt as well.

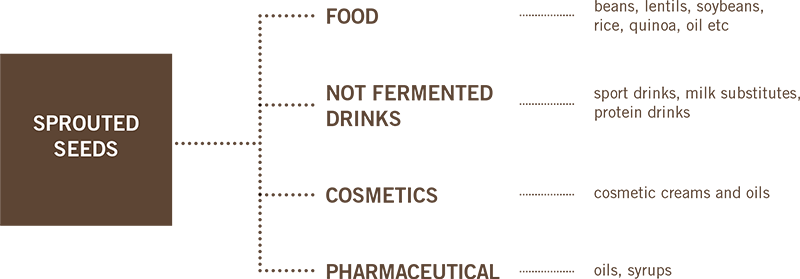

Now even commercial malthouses have a system whereby they can produce small batches of new malts and sprouted seeds. These products can be used in various sectors, from food to beverages, from cosmetics to pharmaceutical products. The potential is manifold to be able to give a significant final added value, also from an economic point of view.

SPROUTED SEEDS

Sprouted seeds are an example of nature’s extraordinary ability to produce energy. Germination is a natural process thanks to which an incredible flow of energy is activated, necessary for the plant to grow, which transforms a nutrient, the seed, into a super nutrient: the sprout.

The properties of a malted/sprouted seed are:

• LESS CALORIES, LESS CARBOHYDRATES

• MORE PROTEINS, VITAMIN B, VITAMIN C, VITAMIN E, BETA-CAROTENE

• MORE NUTRIENTS, AMINO ACIDS AND FIBERS

• LESS ANTI-NUTRIENTS

• MORE DIGESTIBLE BECAUSE ITS RICH IN ENZYMES

• LESS GLUTEN, MORE SUITABLE FOR THOSE WITH FOOD INTOLERANCE

COMPONENTS AND OPERATION OF ZANIN MALTERIES

The manufacturing of malting plants has been a natural step for our company, coming from experience acquired in the production of machines for cereal processing combined with a greater sensitivity in the food industry.

After decades of products obtained from large transformation cycles, there is now a trend towards regionalization. Therefore the production of its own malt has regained importance for small and medium-sized companies. Mostly for craft breweries, terms like "origin" and "territory", now play a key role in their activity.

01 STEEPING VESSEL

The well cleaned and graded product is loaded into the steeping vessel through an auger or other type of conveyor. Once the loading is finished, controlled temperature water is introduced for the steeping phase and, thanks to the forced movement of the water, residual impurities are expelled. The product reaches the desired humidity with alternating phases of steeping and resting times. Once the product is in compliant, it is transferred to the malting drum.

02 MALTING DRUM

The malting drum allows to carry out the subsequent stages of malting: germination and kilning. During these processes, the management software, designed by Zanin, controls the temperature, ventilation, mixing and times set by the user in its recipe. These parameters are essential for determine the final quality of the malt.

03 CLEANING AND MAINTENANCE

Another important aspect of Zanin malting systems is the simplicity of the cleaning and sanification operations. The steeping vessel is equipped with an upper opening from which it is can be internally washed. Access to the part upper is possible through ladder and the inspection platform. The drum has both in the bottom and the top part wide doors that allow, if required, internal access. This guarantees the operator the complete cleaning of the machine from the outside.

04 MINIMALTING SYSTEM

The minimalting system mod. MINIMALT-5, is an All-in-One system where the phases of steeping, germination and kilning take place in the same machine. It is capable of processing 500 kg of incoming product per cycle. The software developed by Zanin allows an automated management of the process, whose work parameters are defined by the user in his own recipe.

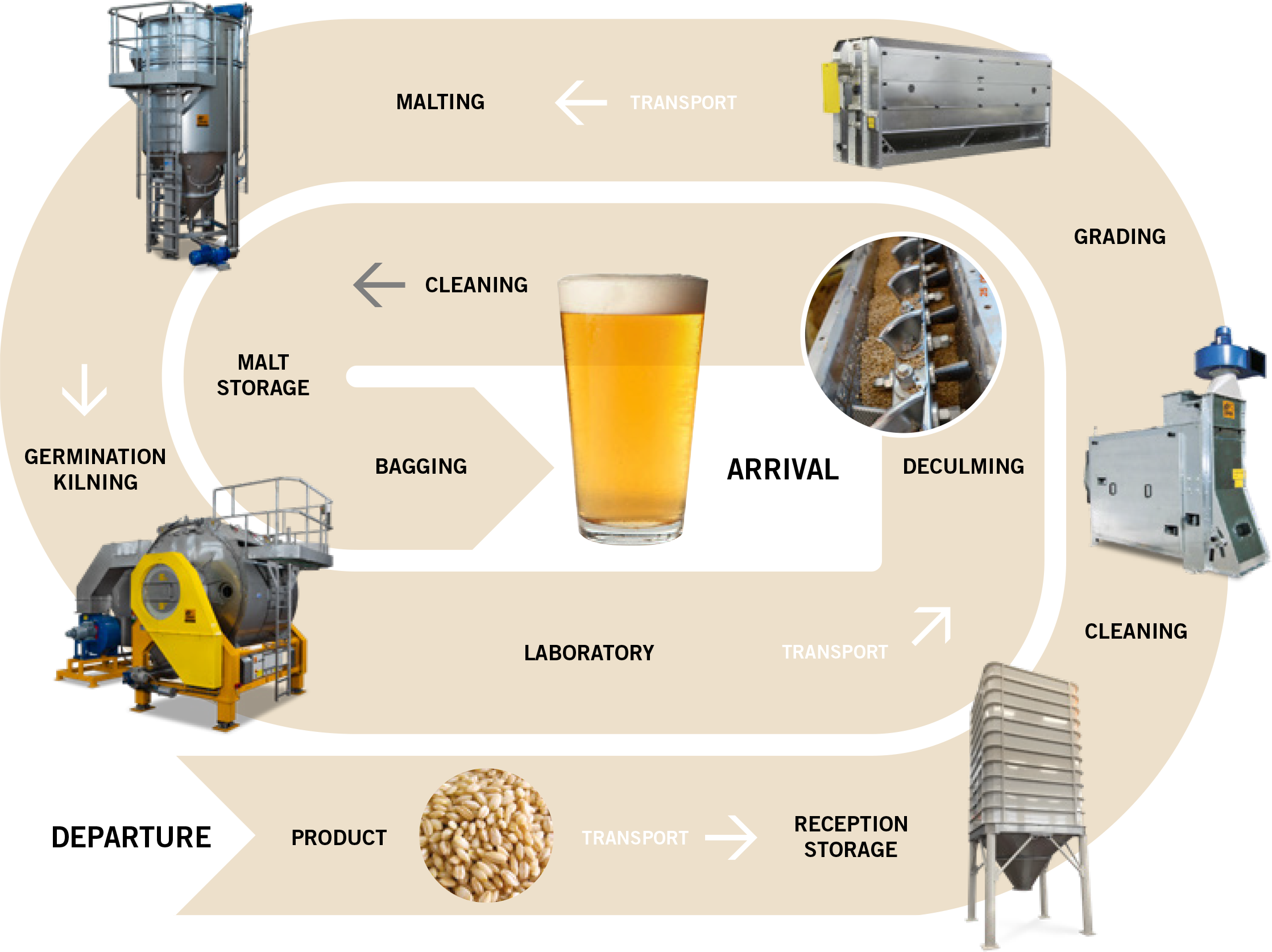

THE PROCESS

Zanin is able to create tailor-made solutions for the customer ranging from the receipt of the raw material up to the packaging of the finished product. It is essential to remember that the product, before the malting process, must be cleaned and graded to obtain that homogeneity defining the final quality of the malt.

PROCESS MANAGEMENT AND CONTROL

To improve productivity in the agri-food industry, automated systems are used to control the entire production organization through interconnection between machines. These systems allow for the collection of all the information necessary for product traceability; they also enable the planning and verification of machine maintenance intervals.

Process management can be done remotely, allowing for monitoring of machine operation, collecting information to send to Big Data, and managing scheduled, extraordinary, and emergency maintenance interventions for the plant. All of this is accessible securely from any location via web, app, or mobile.